Lithium-ion batteries power most of the mobile devices like laptops,

cellphones and portable Play Stations. Longevity of the battery is important to keep these devices active while on the move. But, unfortunately lithium-ion batteries are approaching their energy capacity limits.

cellphones and portable Play Stations. Longevity of the battery is important to keep these devices active while on the move. But, unfortunately lithium-ion batteries are approaching their energy capacity limits.This has prompted researchers to start finding alternatives. For instance, researchers at the University of St. Andrews are developing an air-fuelled battery. In this project, University of Strathclyde and University of Newcastle are partners with University of St. Andrews. The research work is funded by the Engineering and Physical Sciences Research Council. This four-year research project, which began in 2007, is scheduled to end in 2011.

What exists and what's next?

Battery is a deiversified field and there exist many types of batteries, each having its own advantages and disadvantages. In the recent ast, Li-ion and Zinc-air batteries have made a mark in the market. Zinc-aire batteries are electrochemical batteries that charge by drawing oxygen from the air. These have high energy density and are inexpensive to manufacture. They are used in experimental electric vehicles and hearing aids. Lithium-ion batteires are very successful, but these find applications in limited areas of consumer electronics. Producing about two billion units per annum, the industry is still growing.

The applications of lithium batteries, however, can be expanded with development of new techniques. To this end, the researches are trying their hands on lithium-air batteries. Lithium-air batteries are showing great results compared to the earlier lithium-ion batteries. As PetterJ.Hall, professor of chemical engineering, University of Strathclyde, explains, "The capacity of Li-air batteries is 10-2- times greater than traditional Li-ion batteries. These will also be considerably cheaper as they contain very little heavy-metal content.

"Since the new batteires use no toxic trasitional metal, these are environment-friendly, although there is a definite economic advantage to recycling the lithium content in them." T

he lithium-air batteries are also going to become lighter, as cathode has been removed from the battery and oxygen from the air is used as tshe cathode.

he lithium-air batteries are also going to become lighter, as cathode has been removed from the battery and oxygen from the air is used as tshe cathode.What drives Li-air batteries?

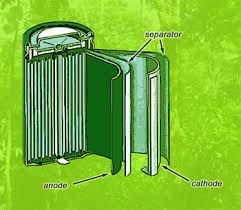

Arthur Dobley, metal air-battery scientist, SBIR proposal manager, Yardney Technical Products, explains, "Lithium-air, and allow it to ract with the lithium metal anode. These are constructed in layers, like sandwich, of the lithium metal anode, separator with electrolyte and then the air cathode. The air cathode is the critical part, and that is where oxygen enters to cells and reacts."

Given below is an explanation of Li-air batteries construction from Arthur Dobley papers and how Li-air pouch cells are used to test the air cathode. Lithium-air batteries are constructed in layers like a sandwich. For experimental purpose, a pouch cell is used, which contains an air cathode inside the Li-air cells. The cell construction further involves layering of the components and sealing of them in plastic packets. The anode, separator, electrolyte and carbon air cathodes are sealed inside the metallised plastic packets.

The future

So far so good, but what is the future of the Li-air battery which is still under development and where can it find applications? Can this battery suffice all the devices? Lot many questions like these need to answered. Yardney Technical Products inc., a subsidiary of ENTER_TEK International focuses on speciality battery technology for research and product development in high-performance niche markets. Kris Johanessen, directior-business development, Yardney Technical Products, says,"The future of lithium-air is continued development of components such as the anode, electrolyte, separator and especially air cathode. Cell packaging and batteiry design will also be developed. That will depend upon applications which include powering; cellphones, laptops, other electronic devices and even some vehicles. The recharge ability of the cell is the biggest unknown at this time. Further evaluation is necessary to optimise the performance of this promising technology. Efforts to increase the number of cycles available as well as reduce packaging size are on the road map to a viable Li-air system."

No comments:

Post a Comment